Others series

TTO & Paging

The paging & TTO thermal transfer all-in-one machine series is an innovative fusion of TTO thermal transfer technology and intelligent paging technology, which perfectly realizes automatic paging feeding and thermal transfer-coding, and can be used with various TTO thermal transfer coding machines.

This model is specially developed for coding soft materials such as various plastic packaging bags, paper, labels, etc. Because the carbon ribbon is used as the printing consumable, it is hygienic, convenient, economical, small in size, simple in process, and beautiful in solid character effect.

FEATURES

SPECS

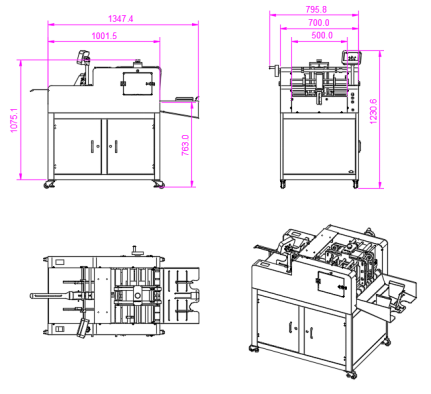

Classic version paging & TTO thermal transfer all-in-one machine

Dimensions

length*width*height=1350*800*1230mm

weight

about 100KG

power supply

220VAC

total power

about 1KW

belt running speed

0-50m/min

control method

PLC+touch screen; double frequency conversion/double DC brushless speed regulation

suitable for product types

various packaging bags, sticky notes, paper and other soft products

to adapt to product specifications

length * width * thickness = (60-300) * (60-400) * (0.1-1) mm

effective printing width adjustment range

300mm (handle adjustment)

SPECS

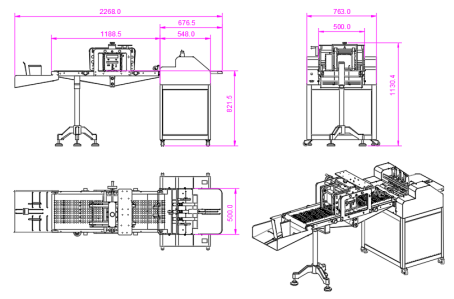

Standard smart paging & TTO thermal transfer all-in-one machine

Dimensions

length * width * height = 2270 * 760 * 820mm (Note: the standard conveyor belt width 385mm, length 1200mm,)

weight

about 200KG

power supply

220VAC

total power

about 1.5KW (including negative pressure adsorption function)

belt running speed

0-50m/min

control method

PLC+touch screen; double DC brushless or double frequency conversion speed regulation

suitable for product types

various packaging bags, sticky notes, paper and other soft products

to adapt to product specifications

length * width * thickness = (60-300) * (60-380) * (0.1-1) mm

effective printing width adjustment range

300mm (handle adjustment)

SPECS

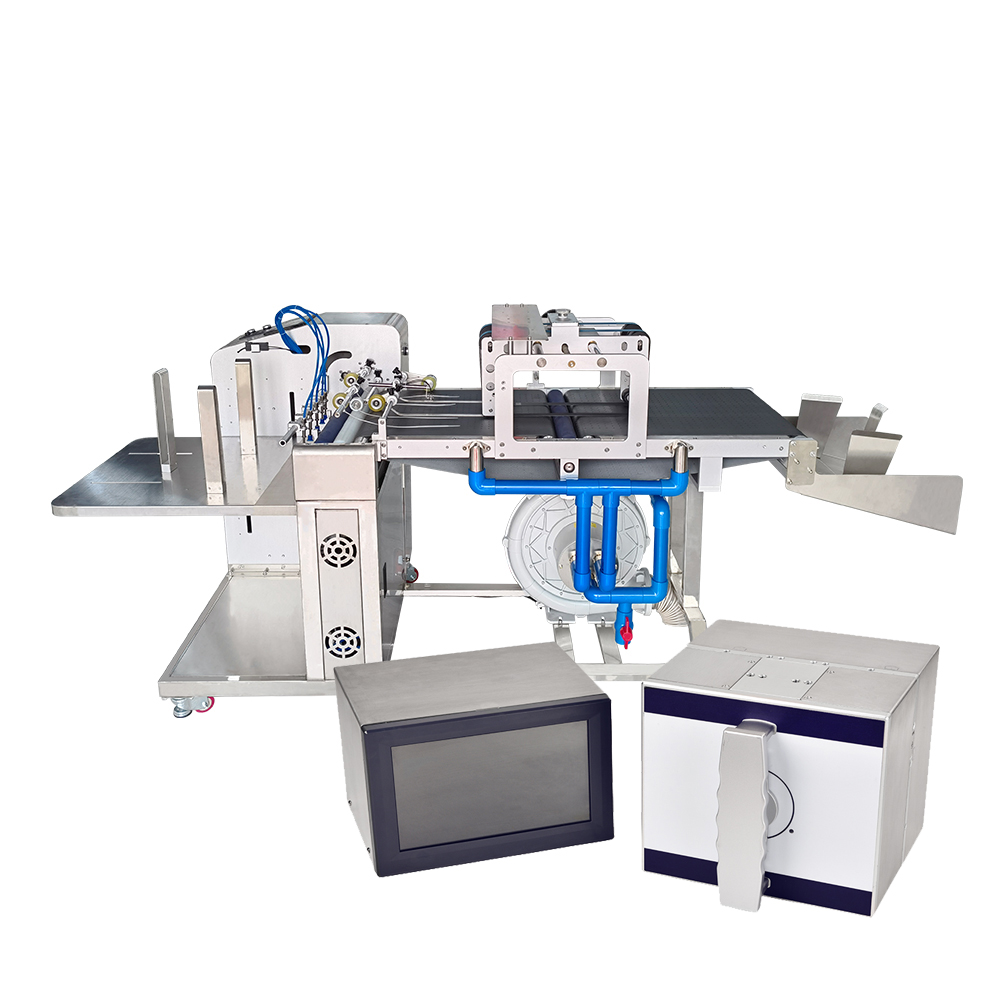

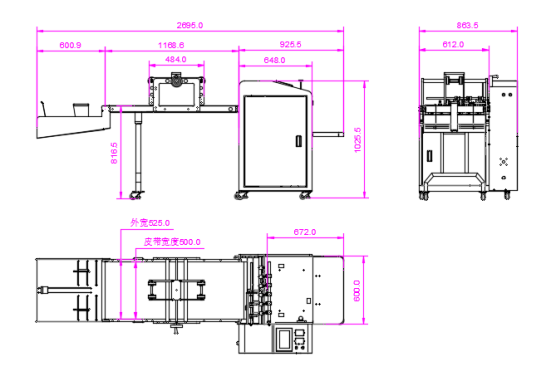

Intelligent upper suction cup paging & TTO thermal transfer all-in-one machine

Dimensions

length * width * height = 2270 * 760 * 820mm (Note: the standard conveyor belt width 385mm, length 1200mm,)

weight

about 250KG

power supply

220VAC

total power

about 1.5KW

belt running speed

0-50m/min

control method

PLC+touch screen; DC brushless or double frequency conversion speed regulation

suitable for product types

various packaging bags, sticky notes, paper and other soft products

to adapt to product specifications

length * width * thickness = (100-600) * (100-500) * (0.1-1) mm

effective printing width adjustment range

400mm (handle adjustment)

SPECS

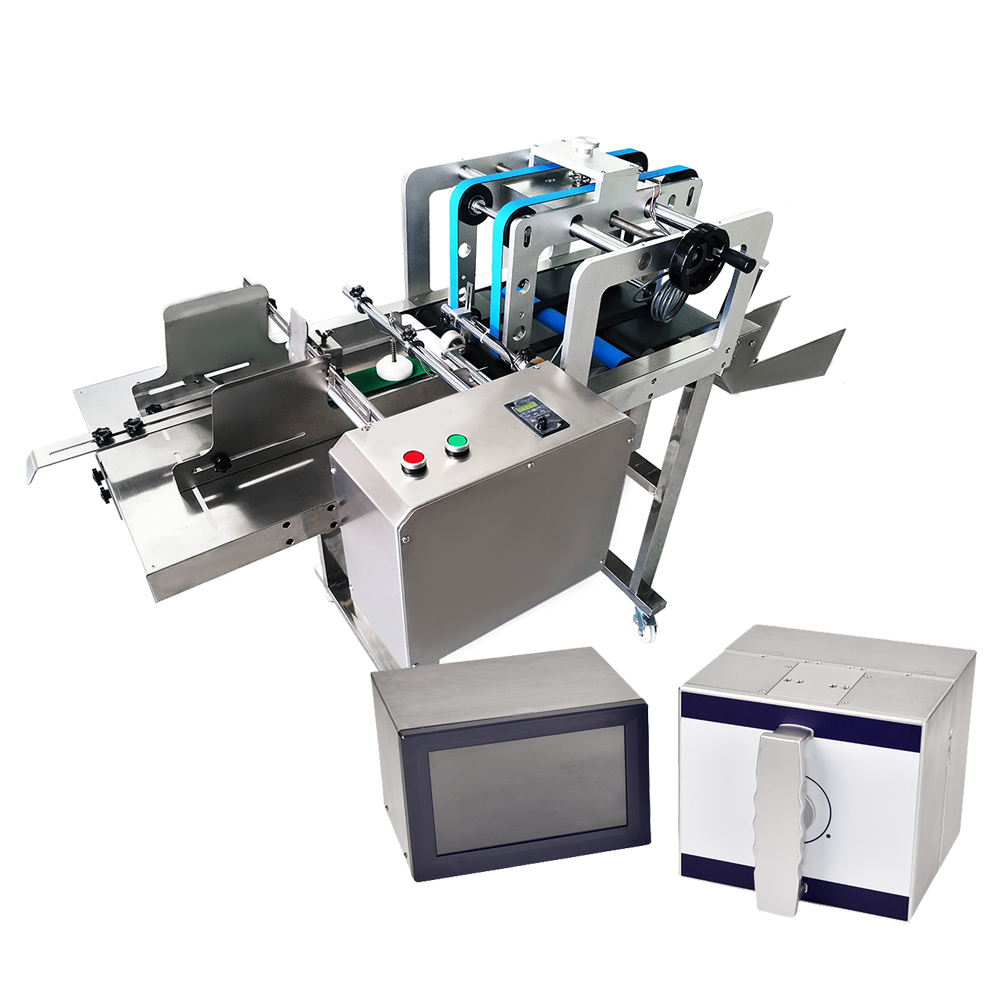

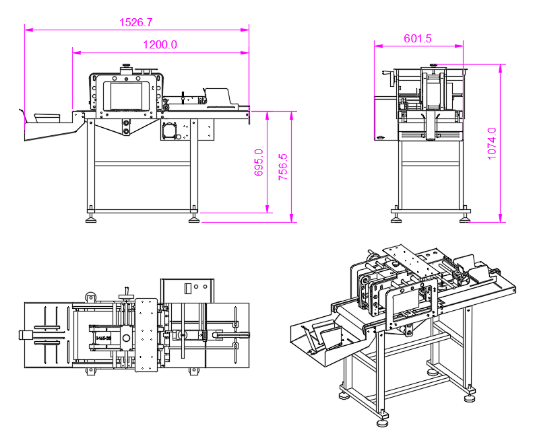

Normal version paging & TTO thermal transfer all-in-one machine

Dimensions

length * width * height = 1525 * 600 * 760mm (note: the standard conveyor belt width 330mm, length 600mm,)

weight

about 100KG

power supply

220VAC

total power

about 1KW

belt running speed

0-50m/min

control method

single DC brushless or single frequency conversion speed regulation

suitable for product types

various packaging bags, sticky notes, paper and other soft products

to adapt to product specifications

length * width * thickness = (60-300) * (60-330) * (0.1-1) mm

effective printing width adjustment range

200mm (handle adjustment)

WARRANTY

30 DAY-MONEY BACK GUARANTEE

It’s perfectly normal for you to be skeptical about investing in a new inkjet printer! That’s why FAITH PRINTER makes every effort to absorb as much risk as possible so that you are free to make the right decision. We want to make it easy for you to prove that our printing systems are quality machines backed by quality support.

As our customers, we want you to be 100% satisfied. FAITH PRINTER guarantees you a 30-day return guarantee window (from the date of receipt) to evaluate your purchase. Click here for details.

2 YEAR LIMITED WARRANTY

FAITH PRINTER warrants its products and parts against defects in materials or workmanship for two (2) years from the original date of receipt. Click here for detail